Wear-Resistant Steel

Wear-resistant steel, often known as abrasion-resistant (AR) steel or by brand names like Hardox, is a specialized alloy steel. Through precise thermal and chemical processes, it achieves unparalleled resistance to abrasion and impact. These high-performance plates are engineered to combat various types of wear, including impact, sliding, and erosive wear. Their unique microscopic structure guarantees exceptional performance even in the harshest working conditions.

Why Industries Demand Wear-Resistant Steel? Key Benefits:

Adopting wear-resistant steel brings significant economic and operational advantages to your business:

- Extended Component Lifespan: By integrating these robust plates, the service life of industrial components dramatically increases, minimizing the need for frequent replacements and repairs.

- Reduced Operational Costs: Longer component life directly translates into substantial savings on maintenance and repair expenditures.

- Lighter Equipment Design: The superior hardness of wear-resistant steel allows for the use of thinner plates, leading to significant weight reduction and enhanced agility of machinery.

- Consistent Performance: These plates deliver stable and predictable performance, even under the most severe operating conditions, ensuring reliability.

- Excellent Processability: Despite their high hardness, wear-resistant steel plates retain good weldability and machinability, offering versatility in fabrication.

Extensive Applications of Wear-Resistant Steel Plates:

Our high-performance wear-resistant steels find broad applications across diverse industries:

- Mining & Mineral Processing: Ideal for crusher liners, excavator buckets, chutes, screens, and hoppers.

- Steel & Cement Industries: Used as lining for industrial mills, fan blades, ladles, and material handling equipment.

- Road Construction & Heavy Machinery: Perfect for bulldozer blades, loader and excavator buckets, and dump truck bodies.

- Recycling & Waste Management: Essential for shredders and waste compactors.

- Agriculture: Applied in plow blades and tillage implements.

- Construction Industry: Crucial for batching plant equipment and concrete mixers.

The Production Process: Quenching & Tempering (Q&T)

Wear-resistant steel is primarily produced through the Quenching & Tempering (Q&T) process, which imbues it with its exceptional properties:

- Quenching: The steel is heated to a high temperature and then rapidly cooled, typically by cold water spraying. This swift cooling leads to the formation of hard crystalline structures within the steel.

- Tempering: The quenched plate is reheated to a lower temperature (below the critical point) and then allowed to cool in open air. This process stabilizes the microstructure, further enhances hardness and toughness, and improves formability.

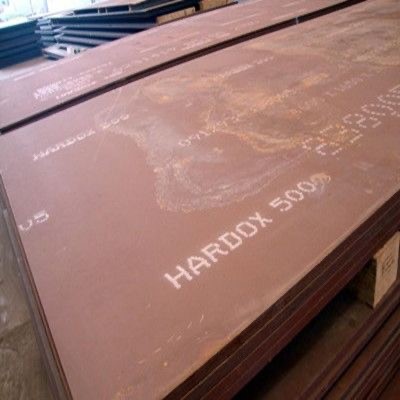

Types of Wear-Resistant Steel Grades:

Wear-resistant plates are available in various grades, each offering distinct hardness and mechanical properties, typically expressed in Brinell Hardness (HBW). Some common grades include:

- 400 HBW (e.g., Hardox 400): A versatile and widely used grade, offering an excellent balance of hardness, toughness, and weldability.

- 450 HBW (e.g., Hardox 450): Provides higher abrasion resistance than the 400 grade while maintaining good formability and weldability.

- 500 HBW (e.g., Hardox 500): Features very high abrasion resistance, making it ideal for environments with severe wear.

- 550 & 600 HBW: Ultra-high hardness grades designed for the most extreme abrasive conditions, such as liners in large crushers.

The selection of the appropriate grade depends on the type and severity of wear, as well as the specific operating conditions of your equipment.

Smart Investment in Wear-Resistant Steel Plates:

While the initial cost of wear-resistant steel might appear higher than conventional steels, it represents a highly profitable long-term investment. The significant reduction in operational costs, enhanced productivity, and minimized downtime far outweigh the initial outlay. Wear-resistant steel genuinely guarantees the extended lifespan of your valuable equipment.

Ready to enhance your equipment’s durability and reduce costs? For expert consultation and to inquire about Hardox prices and other wear-resistant steel grades, please contact our experienced specialists today. We are prepared to provide the optimal solution tailored to your specific project needs.