Polyethylene Pipes | Applications, Specifications, and Technical Classification

Polyethylene (PE) pipe is one of the most widely used and durable types of polymer pipes, employed in the transfer of water, gas, sewage, and industrial fluids. These pipes are categorized into various types based on their raw material, structure, and working pressure. Below, you will get acquainted with different types of PE pipes and their specialized applications.

Classification of Polyethylene Pipes Based on Raw Material

Polyethylene pipes are divided into several main categories based on their density and mechanical properties:

- LDPE (Low-Density Polyethylene): Lower density, suitable for low-pressure applications and drip irrigation.

- MDPE (Medium-Density Polyethylene): Suitable for medium-pressure applications.

- HDPE (High-Density Polyethylene): High density, resistant to high pressure, suitable for industrial uses.

Single Wall PE Pipes

These pipes feature a uniform, smooth wall and are produced in various diameters to withstand different working pressures. Single-wall pipes form the foundation of many piping networks and are an ideal choice for both general and specialized applications due to the following characteristics:

- High Resistance: Excellent stability against internal fluid pressure and thermal fluctuations, ensuring long-term performance.

- Lightweight: Unparalleled ease in transportation and handling, leading to significant reductions in logistics and project execution costs.

- Easy and Fast Installation: High flexibility and the ability to use diverse and simple connection methods minimize installation time and complexity.

- Chemical Resistance: Non-reactive with a wide range of chemicals, acids, bases, and salts, making them highly suitable for corrosive environments.

- Reliable Sealing: Secure and leak-free connections optimize water consumption and prevent resource wastage.

Key Subcategories of Single Wall Polyethylene Pipes:

- High-Pressure Polyethylene Pipes (HDPE)

These pipes, manufactured from High-Density Polyethylene (HDPE) materials to the highest quality standards, are specifically designed for transferring fluids under high pressure. Their exceptional mechanical strength and durability make them an indispensable choice for critical infrastructure:

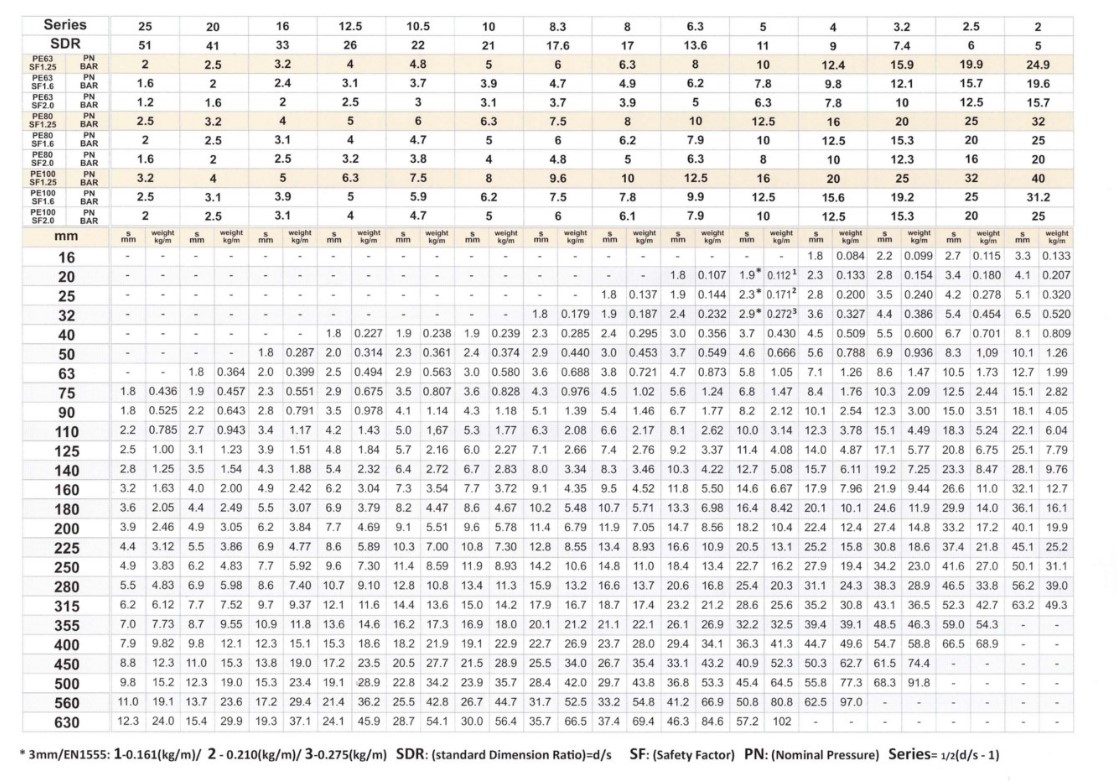

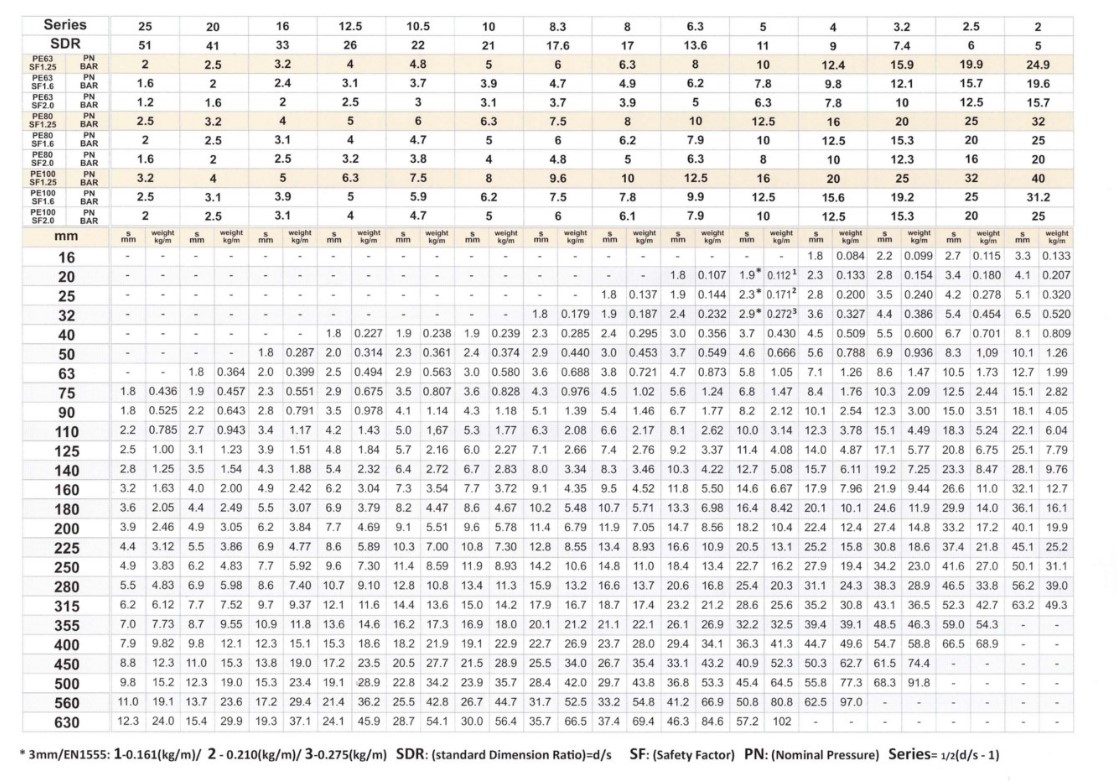

- Extensive Pressure Ratings: Produced in various pressure classes (from 10 to 32 atmospheres and higher), providing adaptability for precise and challenging project requirements.

- Unrivaled Environmental Resistance: Exceptional stability against dynamic and static soil pressures, resistance to corrosive substances, solar ultraviolet (UV) radiation, and internal abrasion, guaranteeing system longevity.

- Versatile Supply: Offered in coiled (long rolls) forms for smaller sizes to facilitate transport and installation, and in long straight segments (6 or 12 meters) for larger diameters.

- Applications: Ideal for main water supply lines in urban and rural networks, natural gas transmission lines, industrial and sanitary wastewater collection and transfer systems, and chemical transport in various industries. They are also widely used in large civil engineering projects, mining, and pressurized agricultural applications.

- Agricultural Polyethylene Pipes (HDPE & LDPE)

This category of single-wall pipes is optimized for irrigation systems in the agricultural sector, playing a vital role in water resource management and enhancing farm productivity. These pipes are manufactured using either HDPE or LDPE materials, depending on specific pressure and flexibility requirements:

- Efficient Water Transfer: An effective option for conveying water from various sources such as wells, ponds, and reservoirs to agricultural fields, orchards, and greenhouses.

- Precise and Uniform Distribution: Suitable for implementing pressurized irrigation systems like drip and sprinkler irrigation, which, in addition to water supply, allow for precise and targeted distribution of fertilizers and agricultural chemicals.

- Resistance to Weather Conditions: High stability against direct sunlight (due to UV additives) and resistance to seasonal temperature fluctuations.

- Flexibility and Easy Installation: Enables quick and cost-effective shaping and installation in uneven agricultural terrains with minimal need for fittings and heavy equipment.

- Resource Conservation: Contributes to significant reduction in water wastage and optimization of energy consumption in irrigation systems.

Double Wall PE Pipes (Corrugated PE Pipes)

Corrugated pipes feature a special dual-wall structure: a corrugated outer wall (for high mechanical strength against external pressures) and a smooth inner wall (to minimize friction and facilitate fluid flow). These pipes are primarily designed for gravity-fed and non-pressure applications:

- Primary Application: Wastewater collection and transfer networks, drainage systems, and surface water management (stormwater).

- Structural Resistance: Withstands traffic loads and soil pressures without deformation, thanks to its corrugated outer structure.

- Large Diameters: Produced in wider diameters compared to single-wall pipes, suitable for large infrastructure projects.

- Efficient Flow: The smooth inner wall prevents sediment accumulation and improves fluid flow.

Conclusion

Polyethylene pipes, in their various forms including single-wall (high-pressure and agricultural) and double-wall (corrugated), offer highly efficient solutions for a wide range of industrial, agricultural, and urban applications due to their high durability, flexibility, and resistance to pressure and corrosion. Selecting the appropriate pipe type and raw material, based on manufacturing standards, intended use, and required pressure, will be the key factor in ensuring optimal system performance and longevity.