Mesh (screen) filters, despite their simple design, are highly effective tools for removing medium to coarse suspended particles from water. These filters easily separate particles such as soil, leaves, sand, and rust by passing water through a mesh made of metal or polymer.

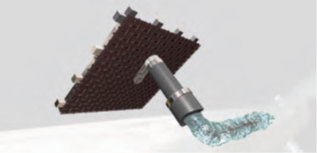

PATENTED nozzle

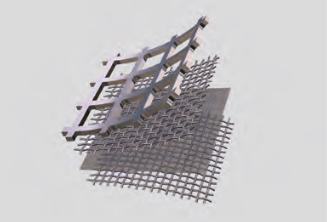

STRUCTURE OF FILTERATION CARTRIDGE

MINIMUM WATER CONSUMTION

Internal view of the filter screen

Advantages:

Key Advantage: Stable and reliable performance in high water volumes with ease of maintenance.

🎯 Applications:

Export Potential: A cost-effective choice for pumping stations, urban irrigation networks, and initial stages of water treatment plants.

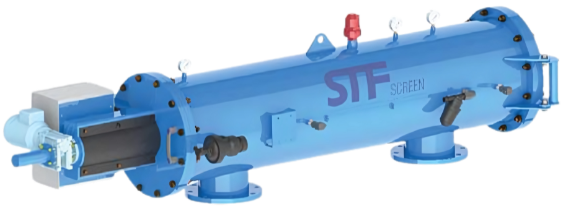

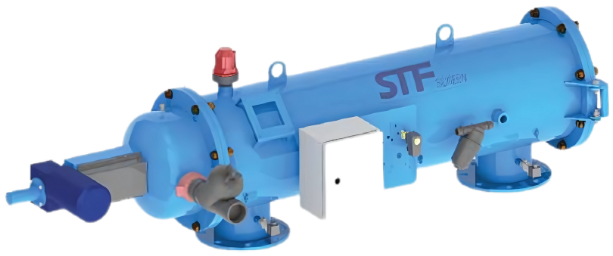

Its hydraulic operation system and the possibility

of operating at very low fl ow rates, due to reduced

consumption of water, make this series the best

solution for municipal and irrigation applications

where no power is available.

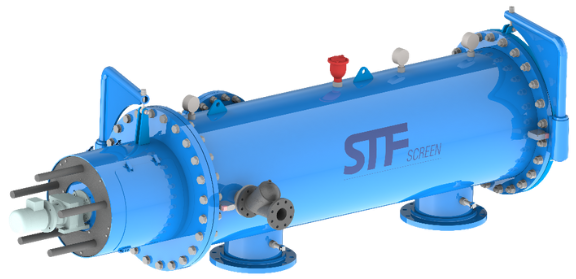

Exceptional performance resulting from low

consumption of water; the electrical actuation

mechanism makes it capable of operating in extreme

conditions. It is especially suitable for low fl ow rates in

municipal and industrial applications.

Its wide range of fi ltration degrees and fl ow rates, along with the fact it can operate

in the most extreme conditions, make this the ideal fi lter for all types of applications.

These models can be grouped to form modular fi ltering stations working as a single

unit with minimal head loss.

Its hydraulic operation system and reduced consumption

of water, make it an ideal solution for municipal and

irrigation applications where no power is available and

higher operation flow rates are required.

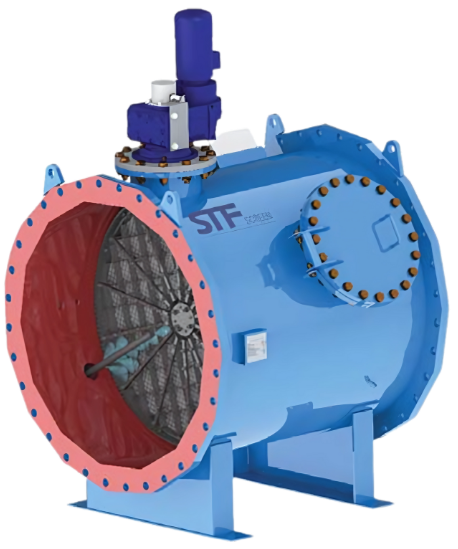

Its internal design with five cartridges inside the body provides it with a large filtration area, thus requiring very

little space for installation. Specially designed for filtration with low filtration degrees and high flow rates in

municipal and industrial applications.

In line, electric, specially designed for mounting in rows

of high flow water pipes. Its operation system allows

very low working pressures, which makes it the ideal

equipment for the protection of pumping systems.